CERTiQ-CS

Main features

• Controlling subunit damper for variab le air flows in system solutions for laboratories, clean rooms, hospitals, etc.

• Communication via Modbus RTU as standard

• Equipped with high-speed actuators to meet safety standards in laboratory environments

• Delivered as part of uLAB and Uranos system solutions for laboratory and safety ventilation

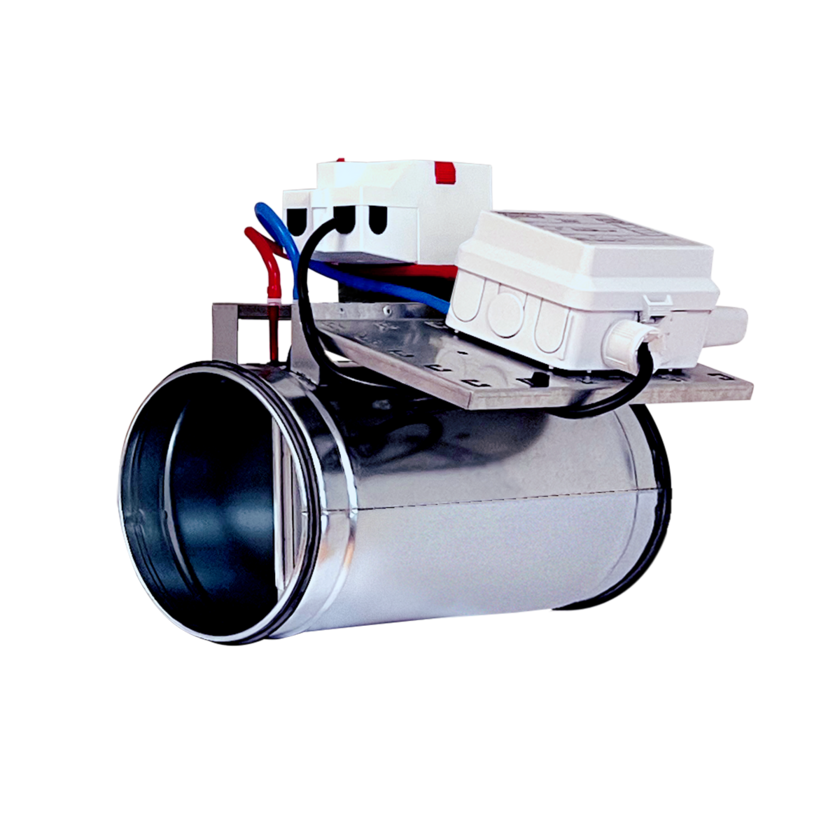

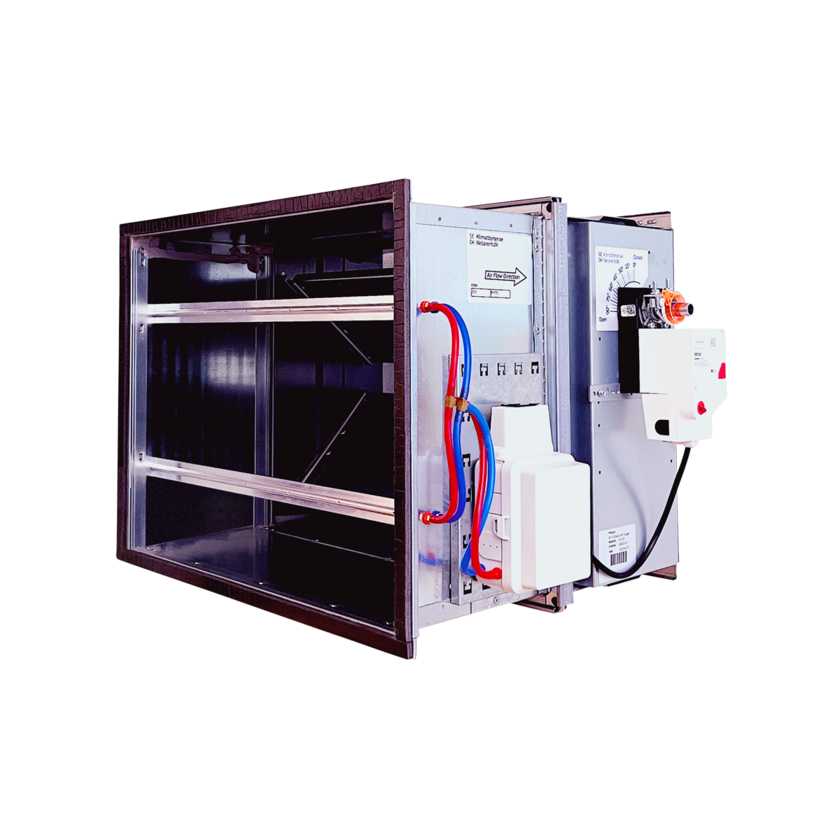

• The product is supplied in circular and rectangular version

Description

CERTiQ dampers and measuring units are designed for use in laboratory and safety ventilation system solutions from Netavent.

• CERTiQ-CS – controlling subunit for flow balancing with signal from summarizing groups of CERTiQ-F, -PM or -M.

In combination with the series' other components, the products can be configured to be included in a variety of system solutions.

• Communication via Modbus RTU alt. iQ-net 2.0 as standard (applies to units equipped with a controller).

• The products are supplied as components in laboratory and safety ventilation system, ControlAir uLAB and can also be used in system Uranos from Netavent.

Material options and finishes:

• Galvanized sheet steel (standard)

• Powder coated finish.

• Circular version can be supplied with damper housing in Magnelis® (≤ Ø400 mm).

• Circular version can be supplied with damper housing in stainless corrosion resistant steel (≤ Ø400 mm), corrosivity class C5 (EN 1.4404).

Circular sizes (mm):

Ø100 / Ø125 / Ø160 / Ø200 / Ø250 / Ø315 / Ø400 / Ø500 / Ø630

Rectangular sizes:

Products in rectangular version are supplied in specific steps within a standard span of W x H dimensions. starting from from 200 x 100 mm (min) to 1600 x 700 mm (max). See product sheet for the specific combinations.

Alternative dimensions can be offered on special order.

• Products in standard version come with housing and blade of galvanized sheet steel, measuring rod of aluminium and measuring hoses of silicone rubber.

• All products meet corrosivity class C3.

• Dampers in the series meet pressure class A with a house in density class C.

Circular products

• Circular products are fitted with damper blades in tightness class 4 unless otherwise specified.

• Circular products are fitted with gaskets of EPDM rubber.

Rectangular products

• Rectangular products are fitted with opposing damper blades in tightness class 3 unless otherwise specified. Blade gaskets are of silicone rubber and damper shafts of galvanized steel.

• Rectangular products are equipped with joint flange profiles for D-type (Drive) or rectangular joint slide profiles/rail. Rails and sealing are not included.

• Circular products have nipple dimensions with rubber gaskets and are mounted with a sliding muff (female slide-in coupling).

• Circular products can be installed in any position and require no maintenance.

• Rectangular products are based on the ordered WxH measurements, which must be taken into account when mounting.

• Rectangular products in standard version come with joint flange profiles for D-type (Drive) or rectangular joint slide profiles/rale. Rales and sealing are not included.

• Rectangular products can also come with frame profiles for bolted assembly (must be specified when ordering).

• In order for the product to provide sufficient measuring accuracy, a straight section of duct must be maintained before the product in air flow direction. This must be taken into account when mounting, see the products operation and maintenance documentation for specific requirements.

• The products are not intended for use in cold or aggressive environments.

• The products are supplied for two available feed alternatives (specified when ordering):

– IPS version (Internal power supply) for 230V feed with an integrated 24V DC power supply.

– EPS version, without power supply for 24V DC feed,for e.g externally mounted power supply.

• The products may only be installed by authorized personnel. All

rules and regulations issued by authorities in the country of usage

must be followed during installation.

• All wiring must be done with the power supply disconnected.

• When installing, space should be reserved for access to the device's actuators and/or readability of units equipped with a display.

• Please see the products operation and maintenance documentation for detailed information on mounting, connection and commissioning.

-

CERTiQ-F-PM-M-CS-D_produktblad-DK (1,490 kB)Product sheetDK2024-11-06

-

CERTiQ-F-PM-M-CS-D_v2.4_DV-DK (1,112 kB)Commissioning/MaintenanceDK2024-11-06

-

CE-Dampers_Netavent-EN-DK (116 kB)CE declarationEN/DK2024-11-04

-

EPD_KB-Netavent_Dampers-and-M-units-EN (1,786 kB)Environmental DeclarationEN2025-10-25

-

CERTiQ-ed3.1_productsheet-EN (1,051 kB)Product sheetEN2025-12-10